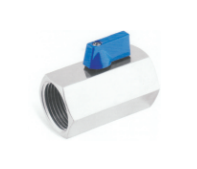

Construction: Three pieces body, Two pieces body, One piece body

Part: Full bore, Reduced bore, two way, three way, mulity port way

Ball Type: Floating ball, the 3-way ball valve

Stem: Blowout-proof stem

Seat sealing: Integral body seat, seat welded and overlaid

Valve Operation: Gear, Pneumatic, Hydraulic, Electric actuators

By passes, locking devices, extended stem, etc

Fire safe: API 607 4th Edition, BS 5351

Other Design: Anti-static design, automatic pressure relief design, emergency grease injection design, drain valve, anti-corrosion design, anti-sulfur design, etc

Design standard: ANSI B16.34, API608,API6D,BS5351,DIN3337.

Wall thickness standard: ANSI B16.34, EN12516-3.

Thread standard: ANSI B1.20.1;DIN 2999/259;ISO 228/1;ISO7/1;JIS B0203.

Socket welding standard: ASME B16.11.

Butt welding end standard: ASME B16.25/ISO1127/EN12627.

Testing standard: API598;EN 12266.

Size range: DN8~DN100, 1/4”~4”

Pressure range: PN16~PN64, JIS10K, 1000~3000PSI

Face to face: ANSI B16.10; DIN 3202 F1,F4; GB/T12221; JIS B2002

Body material: Carbon steel, Stainless steel, Alloy steel, Duplex steel, etc.

NACE MR-01-75/NACE MR-01-03 Special Requirements

Temperature range: -196℃~300℃

Visual inspection: MSS SP-25

Material inspection: PMI Test---Chemical Analysis, UT---Ultrasonic Test, RT---Radio-graphic Test, MT---Magnetic Test, NDT Test Non-destructive